Application Instruction for Automatic Splice (HAS)

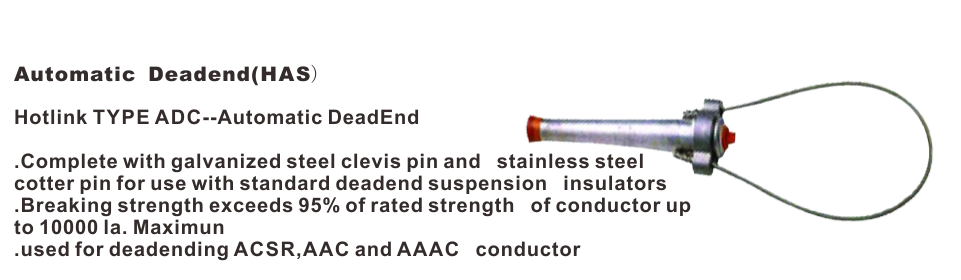

Updated:2013-07-05The working principle of automatic splice/ Deadend, QuickVise / QuickLink is to make the jaws well optioned and moved during application with designed geometries of inner side of tube and outside of the jaws so that the jaws could vise / link the conductor and strand steel wire correctly.

To make the jaws vise / link the conductor and strand steel wire properly, correct application processes will be critical.

For Automatic Splice / Deadend the customer may apply the application following below processes.

A. Select the proper automatic HAS wide range splice for the job. Wire size and type are clearly marked on the splice. The ATS splice is recommended for use on the ACSR, AAAC and AAC conductors and is color-coded for the range of conductor size it accommodates. Please note that proper range is the No. 1 premise for jaws to vise / link the conductor correctly and tightly.

B. Straighten conductor to remove any curvature, so that the wire could be inserted into the tubing and welled optioned with jaws. And this is critical for all the jaws to contact and vise / link the conductor, but not partially.

C. Old Conductors should be cut back sufficiently to remove stretches, burned or annealed strands.

D. Cut conductor square so that all strands are even, in lay and free of burrs. This is also to make sure each jaw could vise / link the conductor correctly, but not partially.

E. Measure the conductor for full insertion and mark with tape or other device which clearly indicates insertion distance (one half the length of the splice).

F. Wire brush the end section thoroughly with a bristle wire brush. This is mainly to remove the scale cinder and make the jaw not only vise / link but bite the conductor properly.

G. ACSR conductor only:

The portion of the ACSR stranding to be inserted into the automatic connector should be thoroughly cleaned with a good quality aluminum conductor cleaner.

H. Although the ATS splice already contains inhibitor on the jaws and ID of the tube, it is recommended that a coat of non-gritted compound be applied to the conductor and the excess wiped off. It is also recommended to wire brush the inhibitor coated conductor once again to assure all the oxides have been removed and inhibitor reaches between the strands.

I. Do not remove the plastic strand guide or internal pilot cup. These components confine and guide the conductor strands for easy insertion.

J. Insert conductor into splice with a smooth straight thrust through the jaws until conductor hits center stop. DO NOT TWIST. Do not push conductor partially in, pause and then continue. Insertion must be accomplished with one continuous thrust. Otherwise one or more jaw might not be able to vise / link the conductor or only partially vise / link the conductor. Check markers for full insertion. If insertion is not complete, conductor will not be gripped and will pull out easily.

K. Before releasing blocks, apply a momentary “hand set” tension to assure proper jaw gripping. As tension is applied, the conductor will move 1/4 inch to 1/2 inch from the end of the splice due to the sliding action of the gripping jaws. This is normal. DO NOT TAP THE SPLICE TO SET JAWS.